Give Yourself a Hand

The use of personal protective equipment (PPE) has been front and center as the current pandemic continues. It has become commonplace to see facial coverings and gloves used to prevent exposure to infectious diseases. But before the pandemic started, PPE played a key role in protecting the health and safety of our labor force. For instance, did you know that gloves are an essential type of PPE used in the workforce? This is in line with OSHA’s 1910.138 standard. There are many types of gloves available for an assortment of industries and applications. This blog aims to highlight how the proper selection and application of gloves should be an integral part of your company’s health and safety program.

Our hands are one of the things that make humans unique. Without them, there are a variety of things we couldn’t do. They are unique and one of humanity’s greatest assets. Hands are critical for one of our five major senses and essential for most tasks performed on the job. Can you imagine trying to work without the use of your hands? This is why an organization’s health and safety program must aim to reduce injury risks to employees’ hands while performing job tasks. Injuries can range from minor cuts and abrasions, to chemical burns, and at worst can lead to amputation. Unfortunately, according to an article in the National Library of Medicine, 20% of disabling workplace injuries involve the hands. It’s safe to say that our hands are one of the most vital parts of our body. So how do we protect them?

Choosing the Right Gloves

As previously mentioned, there are a variety of glove types available, each unique to the different hazards faced in the workplace. Some types of hazards faced in workplaces are sharp edges, chemicals, electricity, excessive vibration, extreme temperatures, and bodily fluids. For each of these hazards, there is a unique glove type that reduces the risks of injury to hands.

Leather, or cut-resistant, gloves can protect you from sharp objects such as knives or the sharp edges of a tool. Specially insulated gloves can protect from extreme temperatures on both the hot and cold spectrum. There is even an anti-vibration gloves out there that prevents injuries from the extreme vibration of tools. Latex, or nitrile, gloves are used to prevent contact with bodily fluids.

But what about chemicals? Are there special gloves just for exposure to chemicals? The answer to that is YES. However, there is not just one type of glove that is used to protect against every chemical. There are many types of gloves used for chemicals: viton, butyl, nitrile, neoprene, and PVC to name a few.

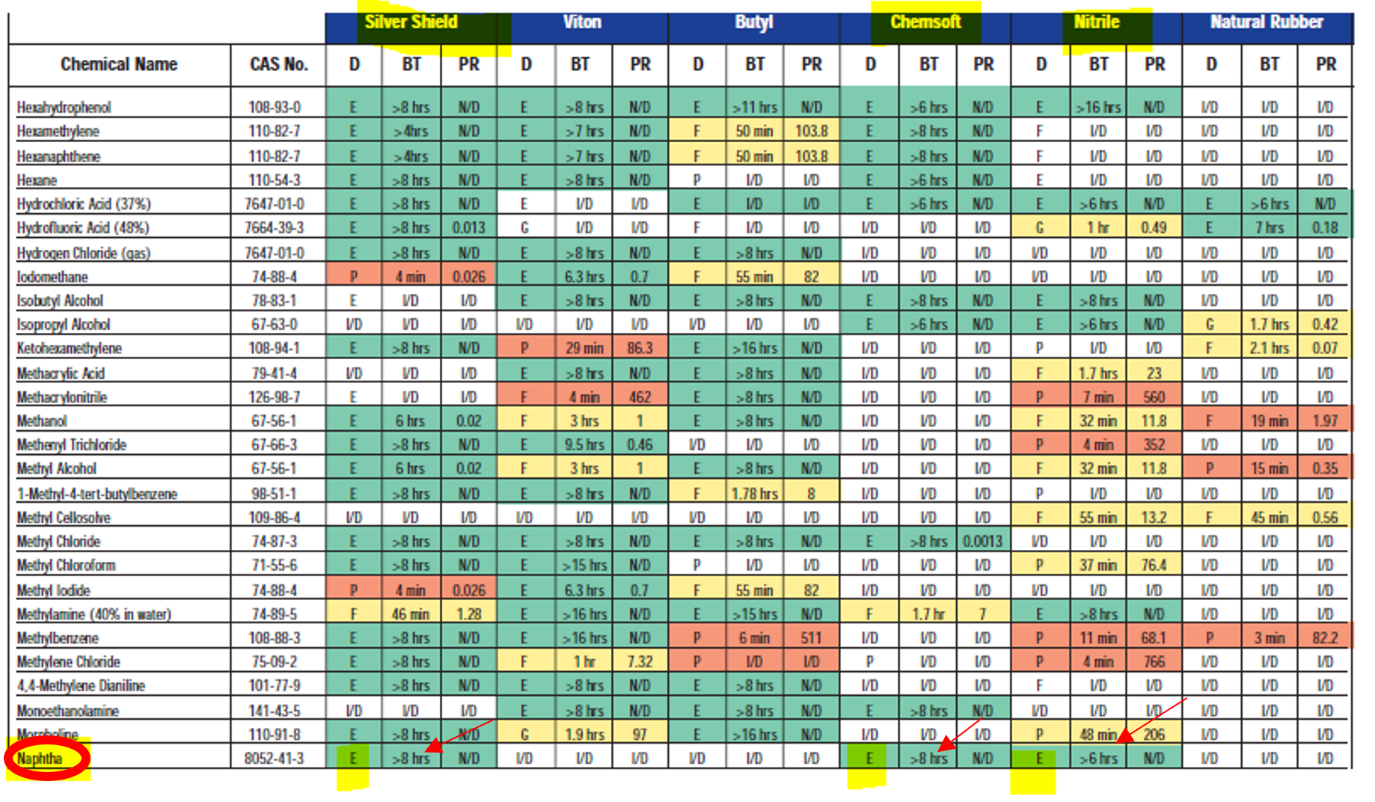

So how do you know which gloves to use for specific chemicals? This is where a gloving chart comes into play. Gloving charts are a unique resource that help us choose the right glove for the any job where chemical hazards are present. Choosing the right glove for specific chemicals is essential to keeping our hands safe and to reducing injury risks. Some of the types of chemical hazards we may encounter are corrosives, solvents, pesticicdes, hydrogen fluoride, cyanuric acid, or battery acids. For each of these categories of chemicals, there are specific gloves that will work best for optimal protection.

Using a Gloving Chart

How do you choose the best glove? One key takeaway is that no glove is completely chemical proof but rather each glove offers varying degrees of chemical resistance. This is where a gloving chart comes in handy. A gloving chart can tell you how resistant a glove is to a specific chemical. To use a gloving chart, simply identify the chemical that you will be working with. From there, read across the chart to identify what type of gloves has the longest breakthrough time (The breakthrough time is the time that elapses from when the glove initially comes into contact with the chemical and when the chemical permeates the glove).

For example, let’s consider the chemical naptha. As you can see on the gloving chart below, the SilverShield and Chemsoft gloves have a breakthrough time of over 8 hours and are therefore rated as excellent gloves to use when dealing with naptha. Comparatively, nitrile gloves have a breakthrough time of over 6 hours. Using the Silvershield or Chemsoft gloves is the better choice depending on how long your exposure will be.

Some gloves have breakthrough times as short as 15 minutes with certain chemicals whereas others have breakthrough times longer than 8 hours. Additionally, the more a chemical is handled, the more it will continue to break down the glove. It is essential that you check the integrity of the glove prior to using it. If a glove shows any signs of wear and tear, it is best to dispose of them and don a new pair of gloves.

Let ASG Help

There is a glove for each kind of hazard in the workplace and the key is choosing the appropriate glove. Using a gloving chart can make it easier to determine which glove to use when working with various types of chemicals in your workplace. Remember, always check to make sure the glove is intact and doesn’t have any rips or tears.

If your business’s EHS program needs updated to include policies, procedures, and training for chemical safety, ASG can help. Our team of experts can walk your organization through the process of designing, developing, and implementing a world-class EHS program that reduces risks and hazards in the workplace while increasing employee morale and production.

Contact us for more information:

Email: instructor@asg-inc.org

Phone: 757-223-7233